State-of-the-art production lines

Our manufacturing processes not only exemplify our commitment to quality but also reflect our dedication to staying at the forefront of electronic manufacturing techniques, ensuring that our products are not just created but masterfully engineered.

As we evolve and adapt to new challenges and technologies, our manufacturing processes continue to set industry benchmarks, underscoring our role as a leader in the electronic manufacturing sector.

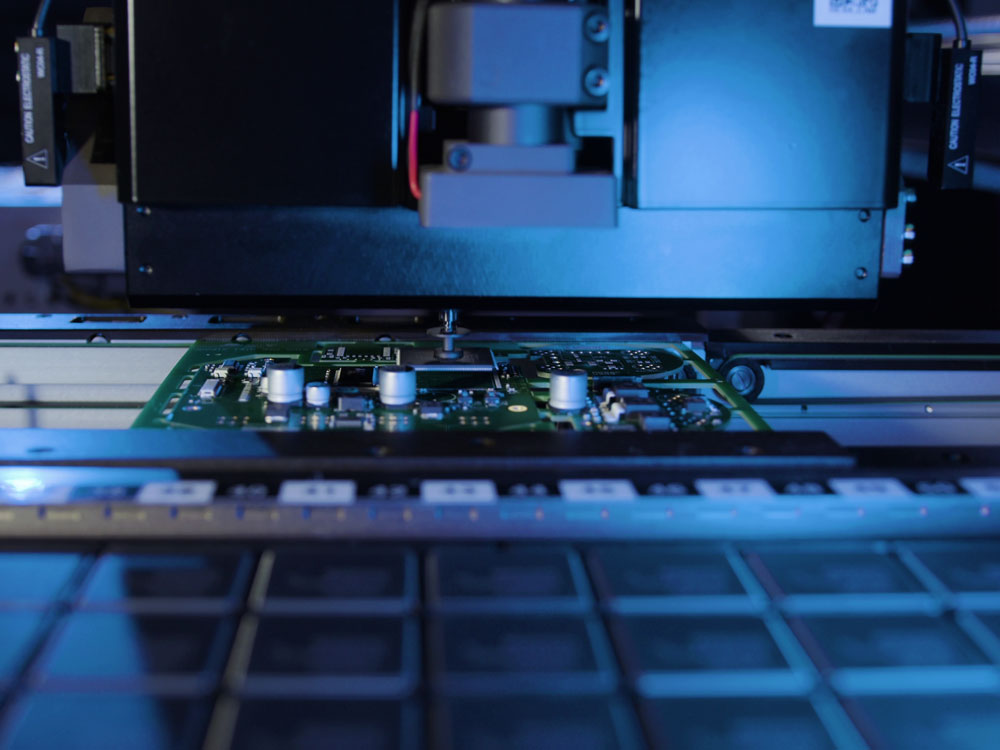

SMT Manufacturing

Utilizing state-of-the-art Surface Mount Technology (SMT), we ensure precise and efficient assembly of electronic components, meeting the highest industry standards for quality and reliability through continuous innovation and rigorous quality control processes.

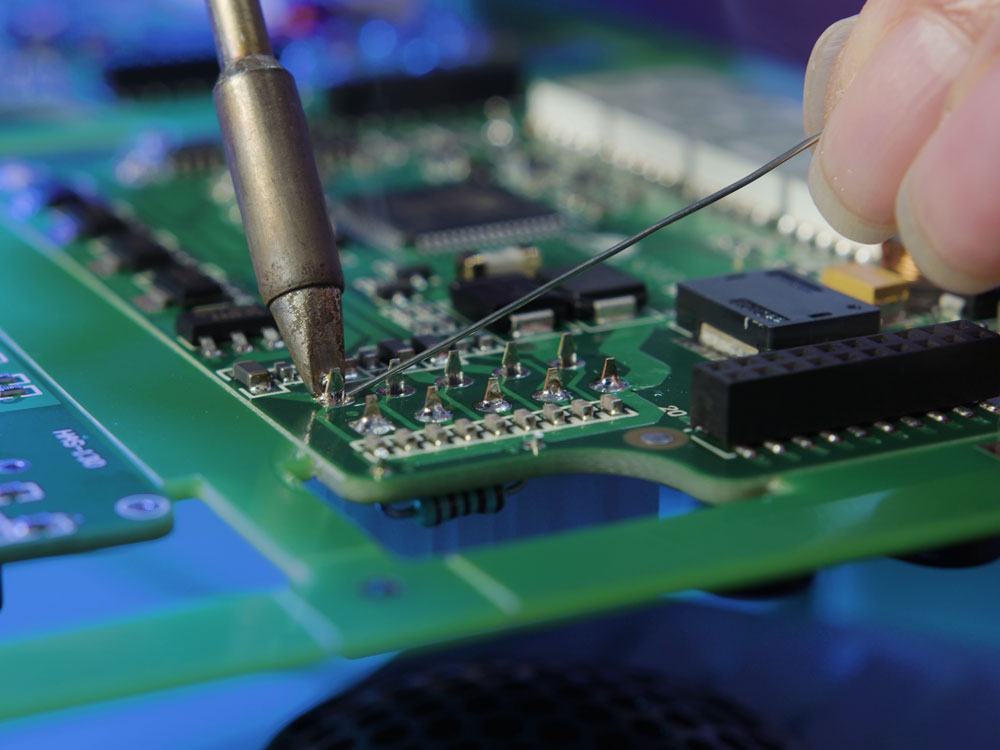

PTH Manufacturing

With our advanced Plated Through-Hole (PTH) manufacturing processes, we guarantee robust and reliable assembly of through-hole components, delivering performance and durability. Furthermore, we conduct ongoing process evaluations to uphold our commitment to quality and to continuously improve our manufacturing techniques.

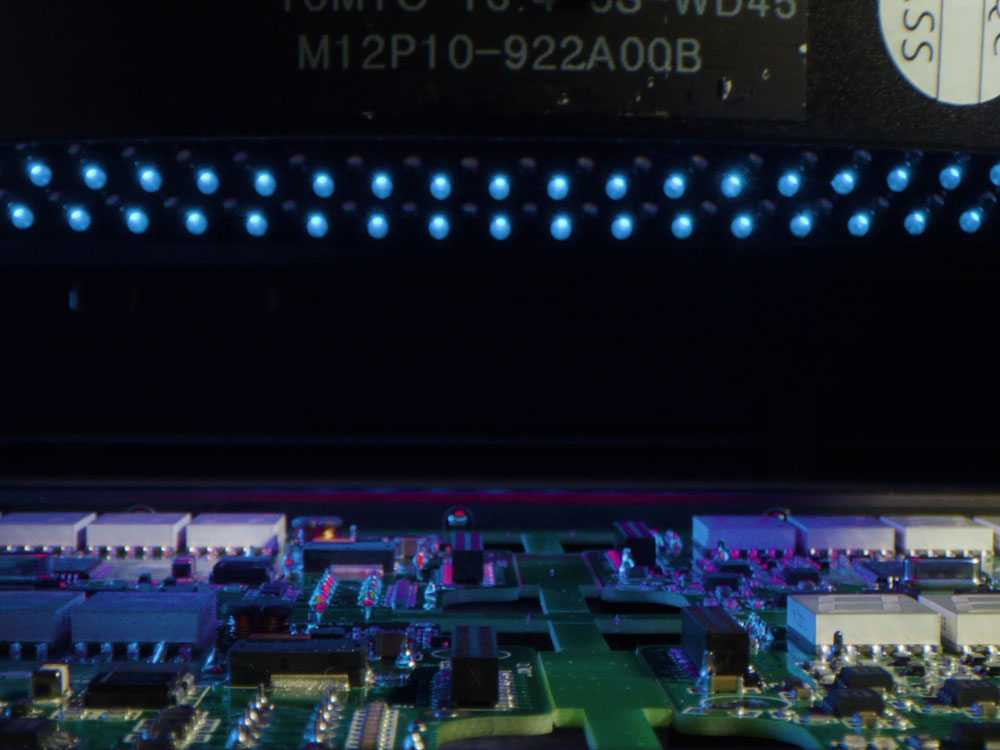

Automated Optical Inspection

As electronic devices become increasingly sophisticated, human inspection alone can not meet our quality standards. We employ AOI machine vision technology to review multiple metrics, including colour verification, pattern matching, component positioning, Blob analysis, optical character recognition, and much more, on every single component.

Advanced X-ray inspection

Demanding requirements for durability and reliability, along with a continuous drive to smaller components means that ensuring quality product manufacture is now more important than ever. X-ray inspection delivers proof of the quality of your product before it leaves our facility.